8g & 9g N2O Cream Charger Cartridges – Factory-Direct Wholesale

Looking for a factory-direct supplier of N2O cream charger cartridges?

At Go Fast Gas, we manufacture food-grade 8g and 9g N2O cartridges with high gas purity, strict leak testing, and fast global delivery — built to support wholesale distributors with consistent quality at unbeatable factory prices.

Your Premier Source for High-Quality Cream Charger N2O Cartridges

Ideal for commercial use, our 8g and 9g cream charger cartridges are specifically engineered for applications including whipped cream, milkshakes, desserts, and culinary creations. Every cartridge is crafted from top-quality materials and rigorously tested to meet strict industry standards—providing your customers with consistent, superior results every time.

We offer of cream charger specifications:

8g Cream charger Cartridge

9g Cream charger Cartridge

Custom N2O Cartridges Tailored to Your Project's Needs

At Go Fast Gas, we understand that your brand’s uniqueness is key to your success. That’s why we offer comprehensive customization options to match your exact requirements:

Custom Packaging & Laser-Printed Branding

Create a distinctive market presence with personalized packaging and precision laser-printed logos directly on cartridges:

10-Piece Boxes

24-Piece Boxes

50-Piece Boxes

600-Piece Boxes

Laser logo Customization

Customized Flavors

Differentiate your products with unique gas flavors:

Watermelon flavor

Strawberry flavor

Pineapple flavor

Mango flavor

OEM flavor

Product Sticker Packaging Customization

Our experienced design team is here to bring your vision to life. Share your ideas with us:

- Logo Name: Provide the name of your logo.

- Specifications: Detail the specifications you require.

- Theme & Color: Describe your product theme and main color.

From logo creation to content design, we offer a seamless, one-stop Free solution.

Experience the Go Fast Gas Advantage

Boost your market competitiveness and customer satisfaction with Go Fast Gas’s premium cream charger cartridges. We are dedicated to providing tailored, dependable solutions that drive your business growth.

Go Fast Gas Parameters Specifications

Discover the Most Comprehensive and Accurate Specifications for Cream Charger Cartridges Online

Product Specifications

| Specifications | Height | Diameter | Weight | Inside Pressure | Material |

|---|---|---|---|---|---|

| 8g | 65 mm | 18 mm | 31.5 g | 55 bar | Carbon Steel |

| 9g | 65 mm | 18 mm | 32.5 g | 55 bar | Carbon Steel |

Transport loading parameters

| 8g / 9g | Quantity | Size (L, W, H) | Weight |

|---|---|---|---|

| Box | 10 pcs / Box | 92*35*65 mm | 0.315 kg |

| Pallet | 28,800 pcs / 2,880 Box | 1050*940*1060 mm | 991 kg |

| 20ft container | 576,000 pcs / 57,600 Box / 20 Pallet | 5900*2350*2390 mm | 19,820 kg |

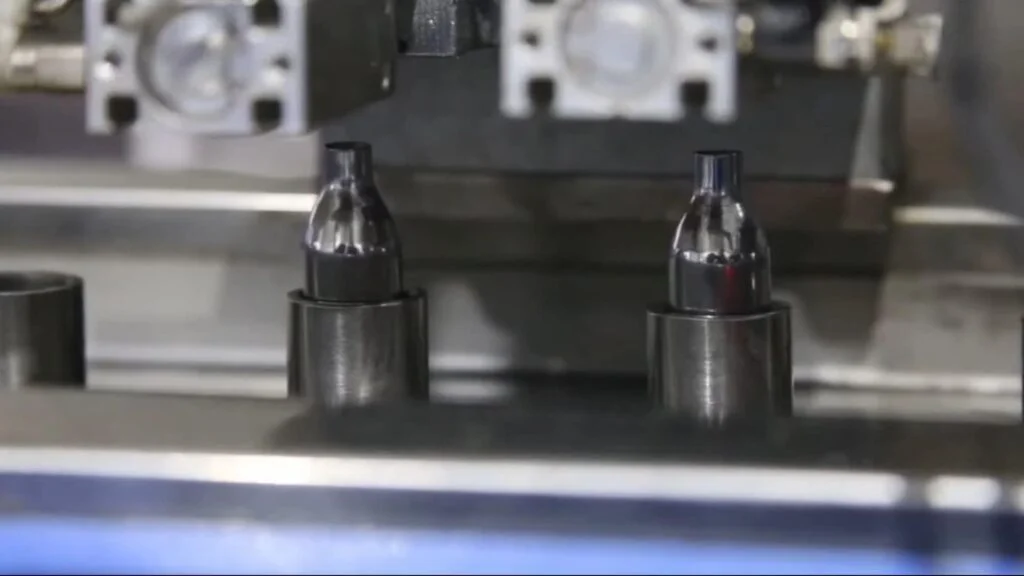

Production process

Explore the Full Production Process Behind Your Cream Chargers Cartridges—See How Quality is Made

1. Internal Inspection: Each shell is checked for cleanliness after electroplating.

2. Seal Placement: A sealing ring is added to inspected cartridges.

3. Automated Filling: Cartridges are inflated and sealed with precision equipment.

4. External Cleaning: Final cleaning ensures surface cleanliness.

5. Color Customization: Optional color customization is available.

6. Weighing: Each cartridge is strictly weighed for consistency.

Compare with Go Fast Gas’s N2O Cartridge Manufacturing

Europe's Premier Factory Exclusively for N2O Cartridges with Fully Automated Production Lines

Equipped with fully automated manufacturing facilities—including two dedicated 20-ton N2O gas storage tanks and 12 state-of-the-art cartridge production lines—Go Fast Gas ensures rapid production, unmatched product consistency, and streamlined supply chain efficiency. Elevate your competitive advantage with superior quality and faster delivery.

N2O Cartridge Production Timeline (Full Container Example)

| Procedure | Go Fast Gas | Other Traditional Factories |

|---|---|---|

| Laser Logo & Packaging Design | 1-3 days | 3-5 days |

| Cartridge Manufacturing | 3-5 days | 5-10 days |

| Quality Inspection & Final Packaging | 1 days | 2-3 days |

| Total Lead Time | 5 days | 10 days |

Shipping Time

Cream Charger HS Code: 28112930

Main Export Port: Antwerp/Hamburg

Shipping schedule from Europe to all over the world:

| Example Country | Transit Time (Days) |

|---|---|

| West Coast of the United States | 1-5 days |

| East Coast of the United States | 1-5 days |

| Canada (major ports such as Vancouver or Toronto) | 1-5 days |

| Western Europe (such as Germany, France, and the United Kingdom) | 1-5 days |

| Eastern Europe (such as Poland and Hungary) | 1-5 days |

| Southeast Asia (such as Singapore and Malaysia) | 1-5 days |

| South Asia (such as India and Pakistan) | 1-5 days |

| Middle East (such as the United Arab Emirates and Saudi Arabia) | 1-5 days |

| Australia and New Zealand | 1-5 days |

| North Africa (such as Egypt and Morocco) | 1-5 days |

| Sub-Saharan Africa (such as South Africa and Nigeria) | 1-5 days |

| Brazil and Argentina | 1-5 days |

| Chile and Peru | 1-5 days |

Please note: Actual delivery times may vary due to several factors. For the most accurate schedule, we recommend checking directly with your freight forwarder or shipping company.

Factors affecting the shipping time of cream chargers

Regulatory Requirements: Cream chargers contain nitrous oxide (a regulated substance), which may require extra review, potentially extending shipping times.

Customs Clearance: Strict import regulations or documentation issues can cause delays during customs inspections.

Port Congestion: High traffic and logistical challenges at busy ports may slow down the loading or unloading of shipments.

Shipping Routes & Transshipments: Longer routes or necessary transshipments can add time to your delivery schedule.

Carrier Efficiency: The speed of your shipment depends on how well your carrier handles dangerous goods.

Seasonal Weather: Severe weather during certain seasons can disrupt transport plans.

Market Demand: During peak periods, limited container and vessel space can lead to longer wait times.

Political & Economic Conditions: Instability in any country involved in the shipment process can also cause delays.

Go Fast Gas N2O Cartridge Quality Assurance

Go Fast Gas focuses on addressing two primary quality concerns in the N2O cartridge industry: leakage and gas purity.

Both factors significantly influence product effectiveness, safety, and user satisfaction.

Leakage Prevention

Cartridge leakage is a common issue within the industry, often resulting from insufficient quality control during production. Go Fast Gas implements a rigorous leakage prevention protocol:

Automated Leakage Testing: Each cartridge undergoes comprehensive automated testing. Statistically, this process reduces cartridge leakage occurrences to fewer than 1 in 10,000.

Automated Manufacturing: Fully automated production lines further decrease the risk of manufacturing errors that can lead to leakage.

This approach ensures reliable cartridge performance and helps maintain the reputation and trustworthiness of your brand.

Gas Purity and Cleanliness

The purity of nitrous oxide directly affects product taste, quality, and safety. Go Fast Gas maintains stringent purity standards:

99.99% Food-Grade N2O: Go Fast Gas fills each cartridge with highly purified, food-grade nitrous oxide.

Comprehensive Cleaning Process: Cartridges undergo multiple cleaning procedures to eliminate potential impurities or residues, ensuring consistent quality.

Compliance and Certifications

Go Fast Gas cartridges adhere to international quality and safety standards, holding certifications such as FDA, GB, ISO, CE, and HACCP. These certifications reflect a commitment to global compliance, quality assurance, and safety standards.

Go Fast Gas’s Commitment

Automated production for enhanced reliability

Rigorous leakage testing procedures

Certified food-grade gas purity

Compliance with international standards

For consistent, high-quality N2O cartridges, consider Go Fast Gas.

Custom Cream Charger With Easy

At Go Fast Gas, we turn complexity into simplicity! Follow these 3 steps to get started today